In the world of precision motion control, the gearbox is the heart of the system. It dictates torque, speed, and, most importantly, the accuracy of movement. For engineers designing robotic arms, CNC machines, or medical devices, the choice often comes down to two dominant technologies: the strain wave gear (often referred to as a harmonic reducer) and the planetary gearbox.

Both are masterpieces of engineering, but they serve different masters. When should you choose a strain wave gear vs planetary gearbox? Is “zero backlash” always the most critical factor, or does stiffness reign supreme? This article provides a detailed, unbiased comparison to help you select the right motion control solutions for your specific application.

How Does a Strain Wave Gear (Harmonic Reducer) Work?

To understand the difference, we must first look inside. A strain wave gear, widely known by the trademark Harmonic Drive®, is a unique type of mechanical gear system that relies on elastic deformation. Unlike traditional rigid gears, it uses a flexible component to transmit torque.

The Three Core Components

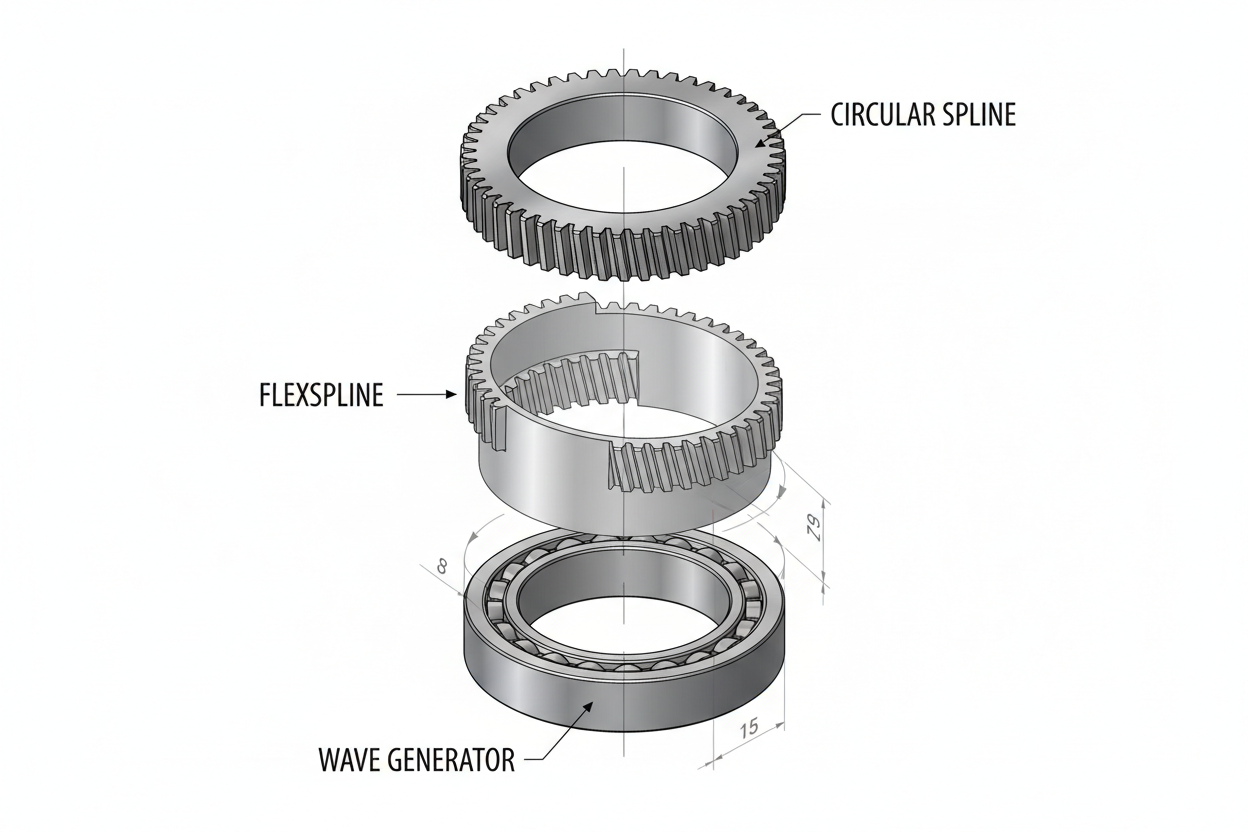

A standard strain wave gear consists of just three parts:

-

Wave Generator: An elliptical cam with a thin ball bearing around it. This is usually the input.

-

Flexspline: A thin, cup-shaped metal cylinder with external teeth. It is flexible and deforms to the shape of the wave generator.

-

Circular Spline: A rigid outer ring with internal teeth. It usually has two more teeth than the Flexspline.

The Principle of Elastic Deformation Gearing

As the elliptical Wave Generator rotates inside the Flexspline, it pushes the Flexspline’s teeth into engagement with the Circular Spline’s teeth at two opposite points. Because of the tooth count difference, for every full rotation of the input, the output moves only a tiny amount (two teeth). This mechanism allows for extremely high reduction ratios (e.g., 100:1) in a very compact space.

Key Inherent Advantages: Compactness and High Ratio

The brilliance of this design lies in its simplicity. It achieves high reduction ratios in a single stage and is incredibly lightweight and compact, making it the standard for robot joints.

How Does a Planetary Gearbox Work?

The planetary gearbox is a more traditional but highly evolved gear system. It is designed for maximum torque transmission and durability.

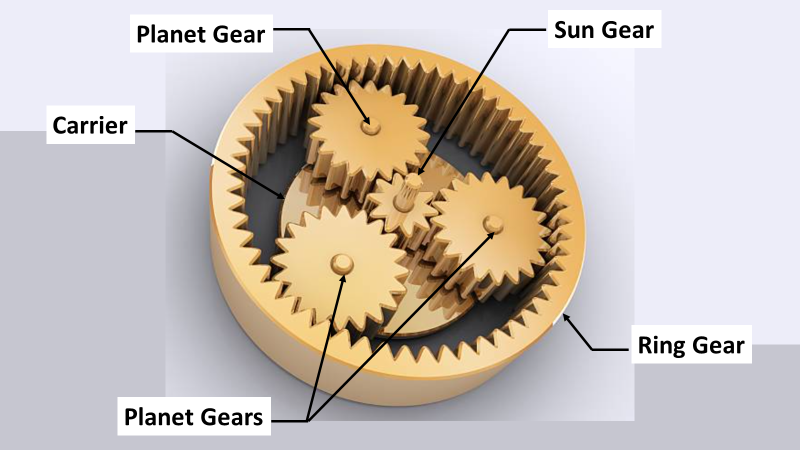

The Anatomy: Sun Gear, Planet Gears, and Ring Gear

The system mimics a solar system:

-

Sun Gear: The central gear connected to the input motor.

-

Planet Gears: Several gears (usually 3 or 4) that rotate around the Sun Gear.

-

Ring Gear: The outer stationary gear with internal teeth.

Understanding Torque Distribution and Load Sharing

When the Sun Gear spins, it drives the Planet Gears, which “walk” along the inside of the Ring Gear. The carrier holding the Planet Gears serves as the output. Because the load is shared among multiple planet gears simultaneously, this design offers exceptional power density.

Key Inherent Advantages: High Torque and Rigidity

Planetary gearboxes are famous for their torsional stiffness. They resist twisting under heavy loads, making them ideal for dynamic applications where the load inertia varies significantly.

Head-to-Head Comparison: Strain Wave Gear vs. Planetary Gearbox

Now, let’s compare them directly across the critical performance metrics that matter to engineers.

Precision and Backlash: The Realm of Zero Backlash

-

Strain Wave Gear: The clear winner for positioning accuracy. Because the Flexspline is preloaded against the Circular Spline, there is absolutely no gap between the teeth. This results in zero backlash (or near-zero, < 1 arc-min). This is crucial for robots that must return to the exact same point every time.

-

Planetary Gearbox: High-precision planetary gears are excellent but typically have a small amount of backlash (usually 1-5 arc-min). While adequate for many industrial tasks, this small “play” can affect the tip position of a long robotic arm.

Torsional Rigidity and Stiffness: Handling High Loads

-

Strain Wave Gear: Because the Flexspline is thin and flexible, it acts slightly like a spring. Under heavy torque, it can wind up, leading to “soft” motion behavior.

-

Planetary Gearbox: This is the stiffness king. The rigid gears and load sharing create a very “stiff” transmission that does not deflect easily under load. This is vital for machining applications where cutting forces would otherwise push the tool off path.

Efficiency and Heat Generation

-

Strain Wave Gear: The constant flexing of metal generates internal friction and heat. Efficiency typically ranges from 70% to 85% and drops at low speeds.

-

Planetary Gearbox: Rolling contact is highly efficient. Planetary gearboxes often achieve efficiencies of 90% to 95% or higher, meaning less energy is lost as heat and smaller motors can often be used.

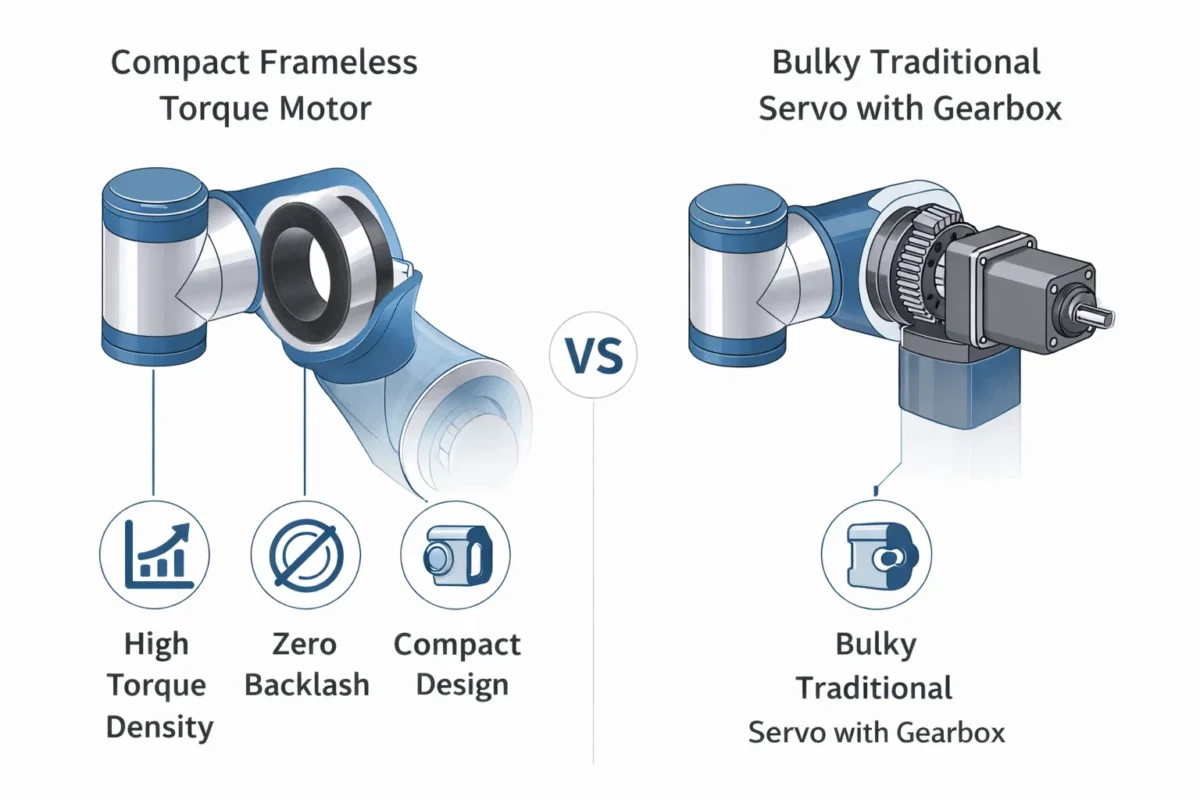

Size, Weight, and Form Factor

-

Strain Wave Gear: Offers the best torque-to-weight ratio for high reduction ratios. It is axially very short (flat), which is perfect for integrating into robotic joints.

-

Planetary Gearbox: Generally longer (axially) than strain wave gears for the same reduction ratio, especially if multiple stages are needed to achieve high ratios (e.g., > 100:1).

Cost and Complexity

-

Strain Wave Gear: Precision manufacturing of flexible metal parts is expensive. These units generally carry a higher price tag.

-

Planetary Gearbox: While high-precision models are not cheap, they are generally more cost-effective than strain wave gears for equivalent torque ratings.

Application Guide: Which Gearbox is Right for You?

Based on the differences above, here is how to choose.

When to Choose a Strain Wave Gear (e.g., Robotic Joints, Medical Robots)

If your application demands:

-

Zero Backlash: Essential for high repeatability.

-

Compactness: Space is extremely limited (e.g., inside a robot elbow).

-

High Reduction Ratio: You need to slow down a high-speed motor significantly in one step.

-

Lightweight: Weight is a penalty (e.g., mobile robots, end-of-arm tooling).

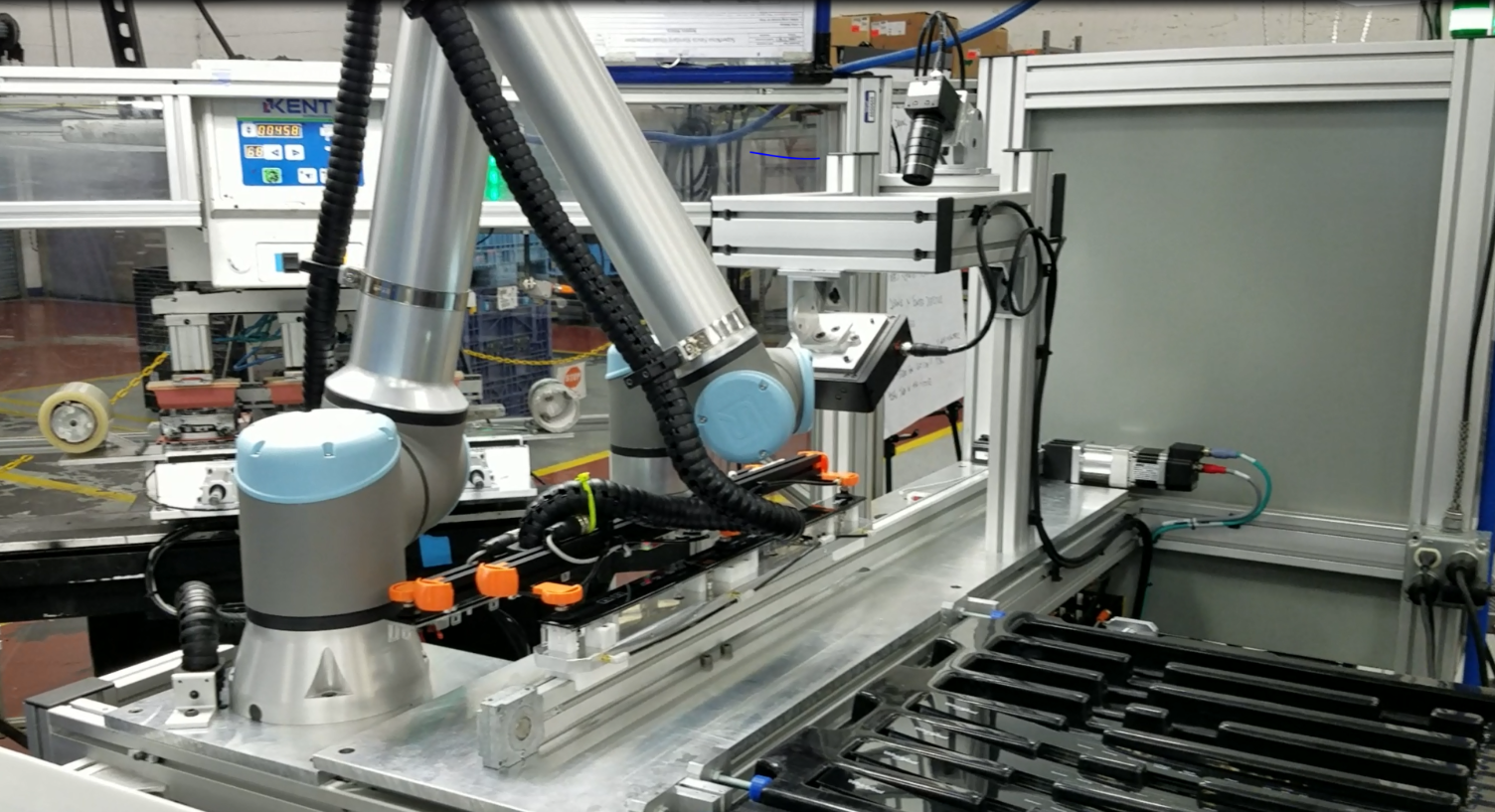

Ideal for: 6-axis industrial robots, collaborative robots (cobots), medical surgical robots, and semiconductor handling equipment. If this matches your needs, you should , which utilize advanced harmonic technology.

When to Choose a Planetary Gearbox (e.g., CNC Machine Tools, Heavy-Duty Actuators)

If your application demands:

-

High Rigidity: You need to resist deflection under heavy, varying loads.

-

High Torque: You need to move heavy masses quickly.

-

High Efficiency: You want to minimize heat and maximize power transfer.

-

Continuous High Speed: The application runs at high RPM for long periods.

Ideal for: CNC machining centers, laser cutting gantries, pick-and-place machines, and heavy automation tracks. For these applications, we recommend you , designed for maximum stiffness and precision.

Conclusion: It’s Not “Better,” It’s “Better For”

There is no single “best” gearbox. The strain wave gear is the master of lightweight precision and compactness, enabling the modern revolution in robotics. The planetary gearbox is the workhorse of industrial automation, offering unmatched stiffness and efficiency.

The choice depends entirely on your specific engineering constraints. If your priority is zero backlash and a hollow design for cabling, a strain wave solution is likely your best bet. If you need maximum rigidity to withstand cutting forces or rapid start-stop cycles with heavy loads, a planetary solution is superior.

Still unsure which technology fits your project? today for a free consultation and calculation assistance.

FAQ Section: Your Precision Gearbox Questions Answered

Q1: Can a planetary gearbox achieve very low backlash? Yes. High-end precision planetary gearboxes can achieve backlash as low as 1-3 arc-minutes. While not theoretically “zero” like a strain wave gear, this is sufficient for many precision applications like laser cutting or printing.

Q2: Why are strain wave gears more common in collaborative robot arms? Cobots require lightweight joints to be safe for human interaction and compact designs to be unobtrusive. The strain wave gear offers the highest torque density and lowest weight, making it the standard for this sector.

Q3: What is a key limitation of a harmonic reducer? The “ratcheting” torque limit and wear life. Because the Flexspline is thin, it can be damaged if the peak torque limit is exceeded (e.g., in a crash). Also, the gear life is generally governed by the fatigue life of the flexible element.

Q4: Which type is generally more expensive?